trommel screens - recycling

Technical support pik@perfopol.pl or Mateusz Woźniak - phone +48 694 431 211

CHARACTERISTICS

Trommel screens manufactured by Perfopol used in rotary screens are mainly used in the processing of mineral raw materials and solid waste. These screens are used for mechanical separation of various materials, the most important of which include:

mineral resources (coal, aggregates, sand)

solid waste (municipal, industrial)

earth

biomass

compost

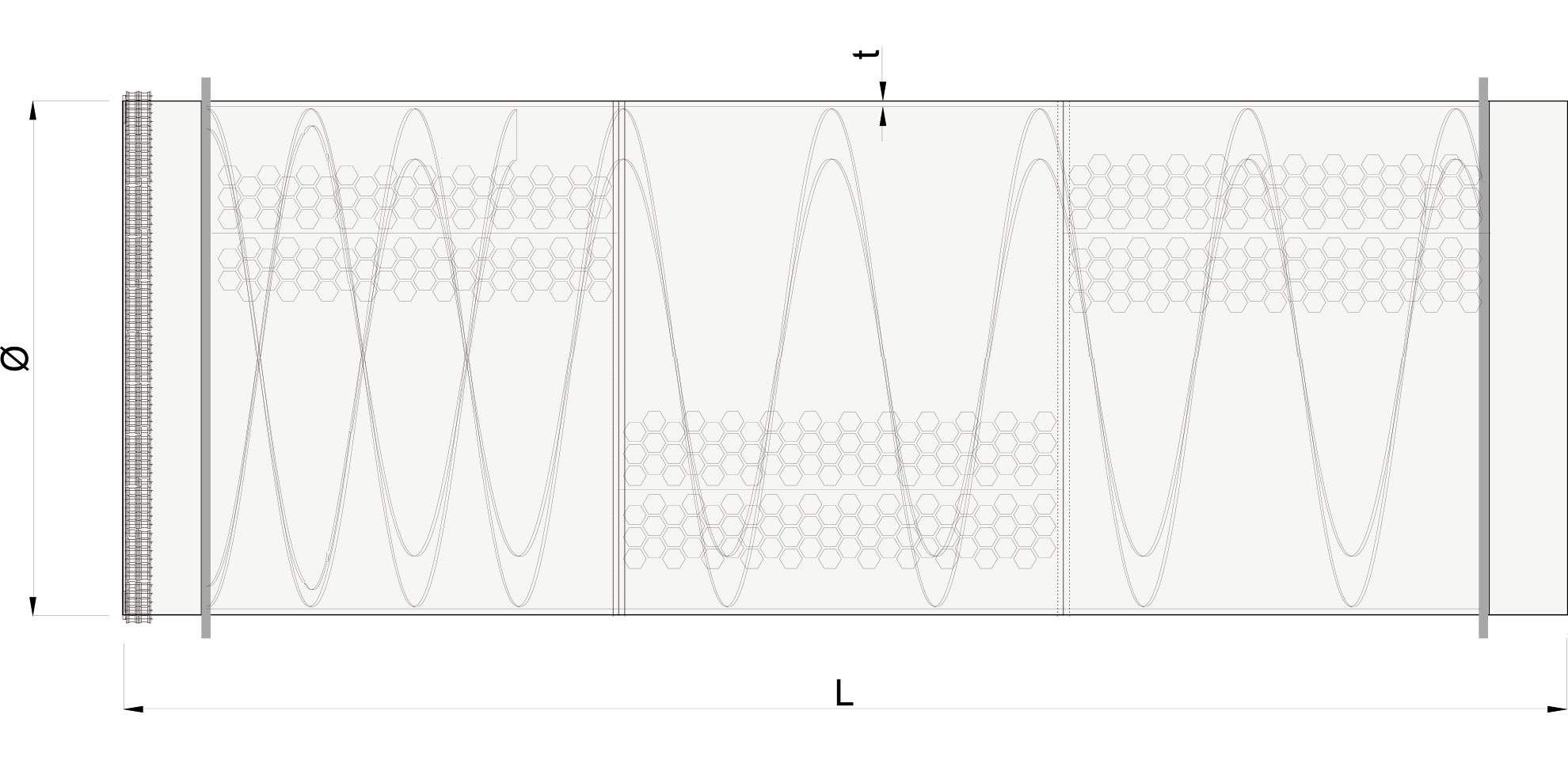

SELECTED TROMMEL MODELS FOR MOBILE MACHINES

| Diameter Ø | Length L | Thickness t | rade of material |

| [mm] | [mm] | [mm] | S235 S355 HARDOX |

| 1400 | 4200 | 5 / 6 / 8 / 10 | |

| 1600 | 4200 | 5 / 6 / 8 / 10 | |

| 1800 | 4500 / 4700 / 7100 | 5 / 6 / 8 / 10 | |

| 2000 | 4500 / 5500 / 7100 | 5 / 6 / 8 / 10 / 12 | |

| 2200 | 5500 / 7500 / 6020 | 6 / 8 / 10 | |

| 2500 | 7000 / 10000 | 6 / 8 / 10 / 12 |

On request, it is possible to manufacture the drum in accordance with client’s specifications

TYPES OF TROMMEL SCREENS:

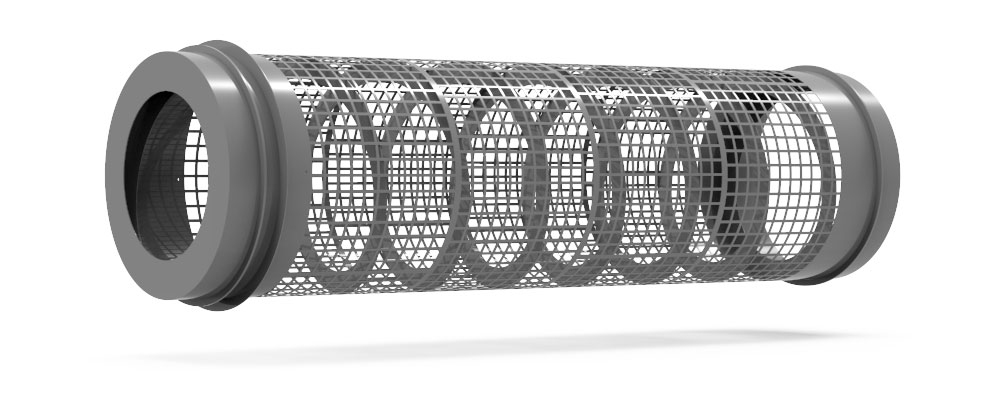

Depending on the type of supporting structure, a distinction is made between mobile and stationary screens. The trommel screens are adapted to the specific screening material and performance requirements. Depending on the applied constructional solutions, trommel screens can be divided into:Monolithic

This type of trommel screen is used in both stationary and mobile machines. They are characterised by high rigidity and provide a compact and durable construction.

They are most often equipped with a spiral ribbon welded to the inner surface of the screen. In addition to its transport function, the spiral additionally stiffens the entire trommel structure, forming a monolithic whole with the other components (i.e. rings, raceways, etc.). The use of this type of trommel design allows for a reduction in tare weight compared to a framework design with replaceable screen inserts. In monolithic trommel screens, the diameter usually does not exceed 2.5m and the length can be up to 10m. The advantage is the quick replacement in the machine and the short retooling time.

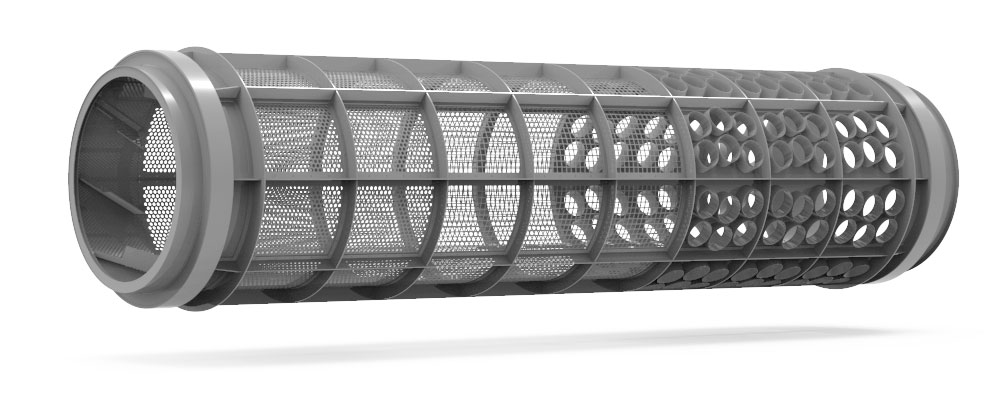

Segmental - with interchangeable screens

The rotary screen consists of a frame and perforated metal sheets or woven mesh attached to it with screws. Such a method of assembly (inside or outside of the structure) allows quick change of the screens according to the processed material.

If woven mesh is used, good self-cleaning properties are additionally achieved through the vibrations created during drum operation. Frame-mounted screens are mostly used in stationary machines. The diameter of the drum is as large as 3m and the total length can reach almost 20m. Due to the weight in excess of 20t, an appropriately sized drive and support structure are required.

Drum screens differ in the type of drive used, which include:

- chain drive – a chain welded to the drum,

- friction drive – the drive roller works on the track or directly on the drum shell

- rack and pinion drive – drum with whole or segment gears

GALLERY OF SELECTED PROJECTS

© Perfopol Sp. z o.o. 2021

76 Radomska St, 27-200 Starachowice, Poland

NIP: 664 000 08 22

phone +48 41 274 58 08

e-mail: biuro@perfopol.pl